Home » Wind Turbine » What are the Advantages and Disadvantages of Wind Turbines?

What are the Advantages and Disadvantages of Wind Turbines?

A wind turbine is a rotating machine which converts the kinetic energy in wind into mechanical energy. If the mechanical energy is then converted to electricity, the machine is called a wind generator, wind turbine, wind power unit (WPU), wind energy converter (WEC), or aerogenerator. Wind turbines can be separated into two types based by the axis in which the turbine rotates.

Turbines that rotate around a horizontal axis are more common. Vertical-axis turbines are less frequently used.

Horizontal Axis Wind Turbines

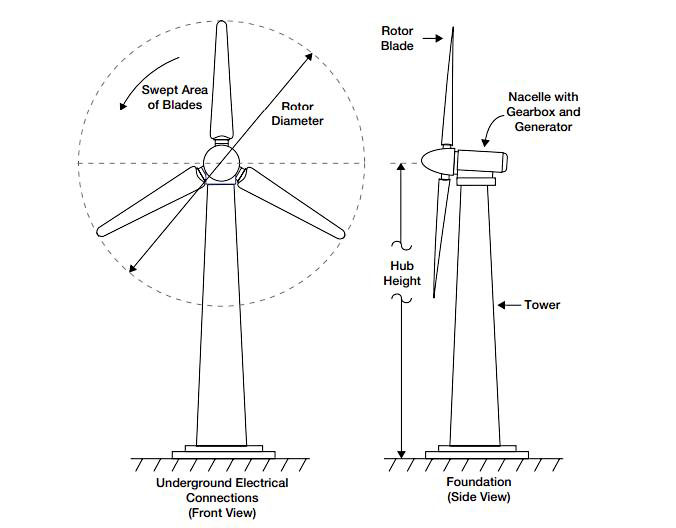

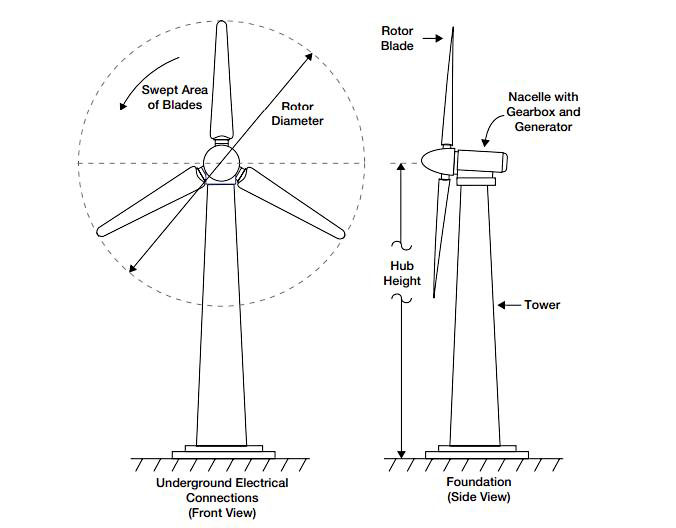

Horizontal-axis wind turbines (HAWT) have the main rotor shaft and electrical generator at the top of a tower, and must be pointed into the wind. Most have a gearbox, which turns the slow rotation of the blades into a quicker rotation that is more suitable to drive an electrical generator.

Since a tower produces turbulence behind it, the turbine is usually pointed upwind of the tower. Turbine blades are made stiff to prevent the blades from being pushed into the tower by high winds. Additionally, the blades are placed a considerable distance in front of the tower and are sometimes tilted up a small amount.

Downwind machines have been built, despite the problem of turbulence, because they don't need an additional mechanism for keeping them in line with the wind, and because in high winds the blades can be allowed to bend which reduces their swept area and thus their wind resistance. Since cyclic (that is repetitive) turbulence may lead to fatigue failures most HAWTs are upwind machines.

HAWT Advantages

HAWT Advantages

Vertical-axis wind turbines (or VAWTs) have the main rotor shaft arranged vertically. Key advantages of this arrangement are that the turbine does not need to be pointed into the wind to be effective. This is an advantage on sites where the wind direction is highly variable. VAWTs can utilize winds from varying directions.

With a vertical axis, the generator and gearbox can be placed near the ground, so the tower doesn't need to support it, and it is more accessible for maintenance. Drawbacks are that some designs produce pulsating torque. Drag may be created when the blade rotates into the wind.

VAWT advantages

VAWT advantages

The ability to change their yaw or compass orientation by turning (using motors) the entire nacelle unit so the rotor is pointed directly into the wind. This process is controlled by wind direction information from nearby wind vanes which are located to minimize the effect due to wake turbulence from the wind turbines.

The ability to change their yaw or compass orientation by turning (using motors) the entire nacelle unit so the rotor is pointed directly into the wind. This process is controlled by wind direction information from nearby wind vanes which are located to minimize the effect due to wake turbulence from the wind turbines.

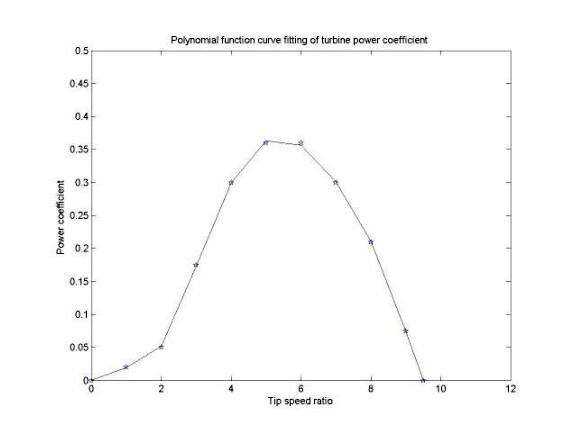

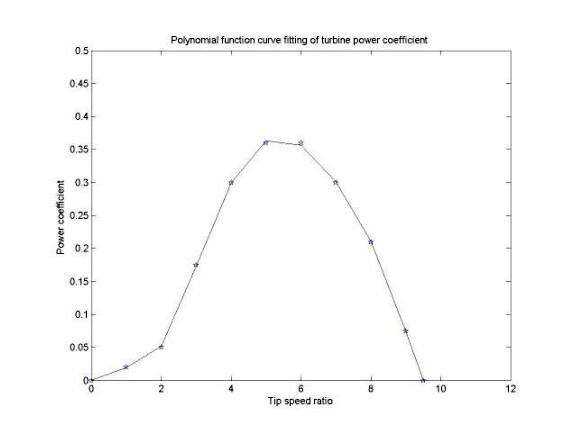

The pitch of the blades which can be changed to keep a near-constant rotation rate under varying wind speeds, where the rotation rate is chosen to optimize the power-generation efficiency of the turbine. Another purpose of both the blade pitch control and yaw Mechanisms is to act as a brake under extremely strong wind condition.

Cut- in speed: The lowest wind speed at which a wind turbine begins producing usable power is called cut-in speed. It is about 3m/s.

Cut-out speed: The highest wind speed at which a wind turbine stops producing power is called cut-out speed. It is about 30m/s.

Turbines that rotate around a horizontal axis are more common. Vertical-axis turbines are less frequently used.

Horizontal Axis Wind Turbines

Horizontal-axis wind turbines (HAWT) have the main rotor shaft and electrical generator at the top of a tower, and must be pointed into the wind. Most have a gearbox, which turns the slow rotation of the blades into a quicker rotation that is more suitable to drive an electrical generator.

Since a tower produces turbulence behind it, the turbine is usually pointed upwind of the tower. Turbine blades are made stiff to prevent the blades from being pushed into the tower by high winds. Additionally, the blades are placed a considerable distance in front of the tower and are sometimes tilted up a small amount.

Downwind machines have been built, despite the problem of turbulence, because they don't need an additional mechanism for keeping them in line with the wind, and because in high winds the blades can be allowed to bend which reduces their swept area and thus their wind resistance. Since cyclic (that is repetitive) turbulence may lead to fatigue failures most HAWTs are upwind machines.

- Variable blade pitch, which gives the turbine blades the optimum angle of attack. Allowing the angle of attack to be remotely adjusted gives greater control, so the turbine collects the maximum amount of wind energy for the time of day and season.

- The tall tower base allows access to stronger wind in sites with wind shear. In some wind shear sites, every ten meters up, the wind speed can increase by 20% and the power output by 34%.

- High efficiency, since the blades always move perpendicularly to the wind, receiving power through the whole rotation. In contrast, all vertical axis wind turbines, and most proposed airborne wind turbine designs, involve various types of reciprocating actions, requiring airfoil surfaces to backtrack against the wind for part of the cycle. Backtracking against the wind leads to inherently lower efficiency.

- The tall towers and blades up to 90 meters long are difficult to transport. Transportation can now cost 20% of equipment costs.

- Tall HAWTs are difficult to install, needing very tall and expensive cranes and skilled operators.

- Massive tower construction is required to support the heavy blades, gearbox, and generator.

- Reflections from tall HAWTs may affect side lobes of radar installations creating signal clutter, although filtering can suppress it.

- Downwind variants suffer from fatigue and structural failure caused by turbulence when a blade passes through the tower's wind shadow (for this reason, the majority of HAWTs use an upwind design, with the rotor facing the wind in front of the tower).

- HAWTs require an additional yaw control mechanism to turn the blades toward the wind.

Vertical-axis wind turbines (or VAWTs) have the main rotor shaft arranged vertically. Key advantages of this arrangement are that the turbine does not need to be pointed into the wind to be effective. This is an advantage on sites where the wind direction is highly variable. VAWTs can utilize winds from varying directions.

With a vertical axis, the generator and gearbox can be placed near the ground, so the tower doesn't need to support it, and it is more accessible for maintenance. Drawbacks are that some designs produce pulsating torque. Drag may be created when the blade rotates into the wind.

- A massive tower structure is less frequently used, as VAWTs are more frequently mounted with the lower bearing mounted near the ground.

- Designs without yaw mechanisms are possible with fixed pitch rotor designs.

- A VAWT can be located nearer the ground, making it easier to maintain the moving parts.

- VAWTs have lower wind startup speeds than HAWTs. Typically, they start creating electricity at 6 M.P.H. (10 km/h).

- VAWTs may have a lower noise signature.

- Most VAWTs produce energy at only 50% of the efficiency of HAWTs in large part because of the additional drag that they have as their blades rotate into the wind.

- While VAWTs' parts are located on the ground, they are also located under the weight of the structure above it, which can make changing out parts nearly impossible without dismantling the structure if not designed properly.

- Having rotors located close to the ground where wind speeds are lower due to wind shear, VAWTs may not produce as much energy at a given site as a HAWT with the same footprint or height.

- Because VAWTs are not commonly deployed due mainly to the serious disadvantages mentioned above, they appear novel to those not familiar with the wind industry. This has often made them the subject of wild claims and investment scams over the last 50 years.

The pitch of the blades which can be changed to keep a near-constant rotation rate under varying wind speeds, where the rotation rate is chosen to optimize the power-generation efficiency of the turbine. Another purpose of both the blade pitch control and yaw Mechanisms is to act as a brake under extremely strong wind condition.

Cut- in speed: The lowest wind speed at which a wind turbine begins producing usable power is called cut-in speed. It is about 3m/s.

Cut-out speed: The highest wind speed at which a wind turbine stops producing power is called cut-out speed. It is about 30m/s.

Post a Comment:

You may also like:

Featured Articles

Horizontal Axis vs. Vertical Axis

Wind turbines are machines that generate electricity from the kinetic energy of the wind. In history, they were more ...

Wind turbines are machines that generate electricity from the kinetic energy of the wind. In history, they were more ...

Wind turbines are machines that generate electricity from the kinetic energy of the wind. In history, they were more ...

Wind turbines are machines that generate electricity from the kinetic energy of the wind. In history, they were more ...Horizontal Axis Wind Turbine Design

Today, the most common design of wind turbine is the horizontal axis wind turbine (HAWT). That is, the axis of rotation is ...

Today, the most common design of wind turbine is the horizontal axis wind turbine (HAWT). That is, the axis of rotation is ...

Today, the most common design of wind turbine is the horizontal axis wind turbine (HAWT). That is, the axis of rotation is ...

Today, the most common design of wind turbine is the horizontal axis wind turbine (HAWT). That is, the axis of rotation is ...Overvoltage Protection for Wind ...

Due to their principle of operation, wind turbines have to be set up outdoors and are used in a wide range of ...

Due to their principle of operation, wind turbines have to be set up outdoors and are used in a wide range of ...

Due to their principle of operation, wind turbines have to be set up outdoors and are used in a wide range of ...

Due to their principle of operation, wind turbines have to be set up outdoors and are used in a wide range of ...What is a Wind Turbine?

Wind turbines are devices that convert the kinetic energy from the wind into mechanical power, which can then be used to generate ...

Wind turbines are devices that convert the kinetic energy from the wind into mechanical power, which can then be used to generate ...

Wind turbines are devices that convert the kinetic energy from the wind into mechanical power, which can then be used to generate ...

Wind turbines are devices that convert the kinetic energy from the wind into mechanical power, which can then be used to generate ...Household Wind Energy System Components

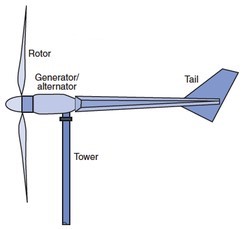

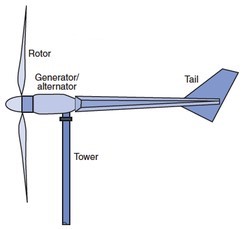

Basic parts of home wind energy systems generally comprise a rotor, a generator or alternator mounted on a frame, a tail ...

Basic parts of home wind energy systems generally comprise a rotor, a generator or alternator mounted on a frame, a tail ...

Basic parts of home wind energy systems generally comprise a rotor, a generator or alternator mounted on a frame, a tail ...

Basic parts of home wind energy systems generally comprise a rotor, a generator or alternator mounted on a frame, a tail ...