Home » Wind Turbine » What is the Status of Wind Turbine Technology?

What is the Status of Wind Turbine Technology?

Wind energy conversion systems can be divided into those that depend on aerodynamic drag and those that depend on aerodynamic lift. The early Persian (or Chinese) vertical axis wind wheels utilised the drag principle. Drag devises, however, have a very low power coefficient, with a maximum of around 0.16.

Modern wind turbines are based predominately on aerodynamic lift. Lift devices use airfoils (blades) that interact with the incoming wind. The force resulting from the airfoil body intercepting the airflow consists not only of a drag force component in the direction of the flow but also of a force component that is perpendicular to the drag: the lift forces. The lift force is a multiple of the drag force and therefore the relevant driving power of the rotor. By definition, it is perpendicular to the direction of the air flow that is intercepted by the rotor blade and, via the leverage of the rotor, it causes the necessary driving torque.

Modern wind turbines are based predominately on aerodynamic lift. Lift devices use airfoils (blades) that interact with the incoming wind. The force resulting from the airfoil body intercepting the airflow consists not only of a drag force component in the direction of the flow but also of a force component that is perpendicular to the drag: the lift forces. The lift force is a multiple of the drag force and therefore the relevant driving power of the rotor. By definition, it is perpendicular to the direction of the air flow that is intercepted by the rotor blade and, via the leverage of the rotor, it causes the necessary driving torque.

Wind turbines using aerodynamic lift can be further divided according to the orientation of the spin axis into horizontal axis and vertical axis turbines. Vertical axis turbines, also known as Darrieus turbines after the French engineer who invented them in the 1920s, use vertical, often slightly curved, symmetrical airfoils. Darrieus turbines have the advantage that they operate independently of the wind direction and that the gearbox and generating machinery can be placed at ground level. High torque fluctuations with each revolution, no self-starting capability as well as limited options for speed regulation in high winds are, however, major disadvantages. Vertical axis turbines were developed and commercially produced in the 1970s until the end of the 1980s. The largest vertical axis wind turbine was installed in Canada, the Ecole C with 4200 kW. Since the end of the 1980s, however, the research and development of vertical axis wind turbines has almost stopped worldwide.

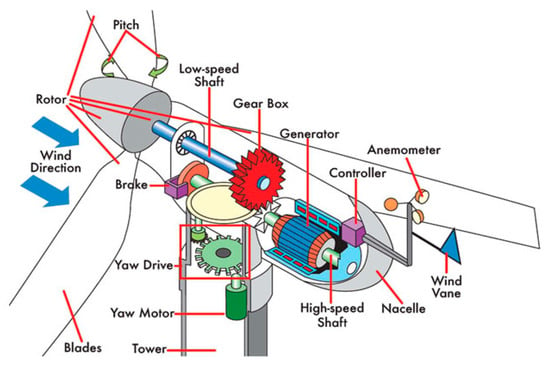

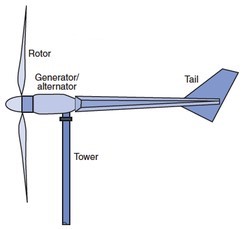

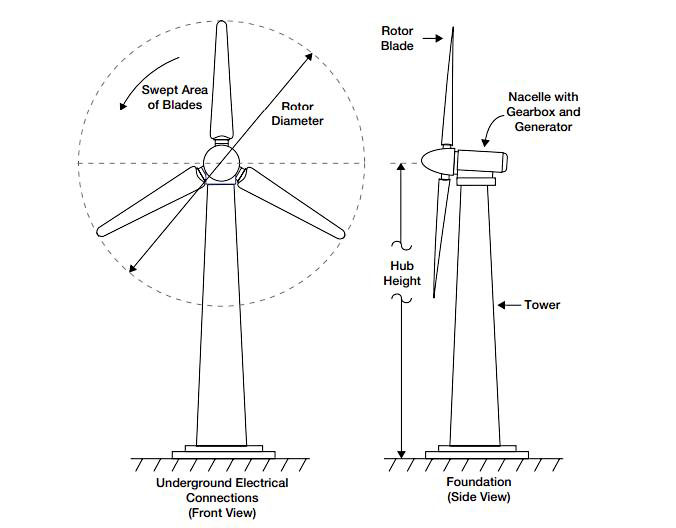

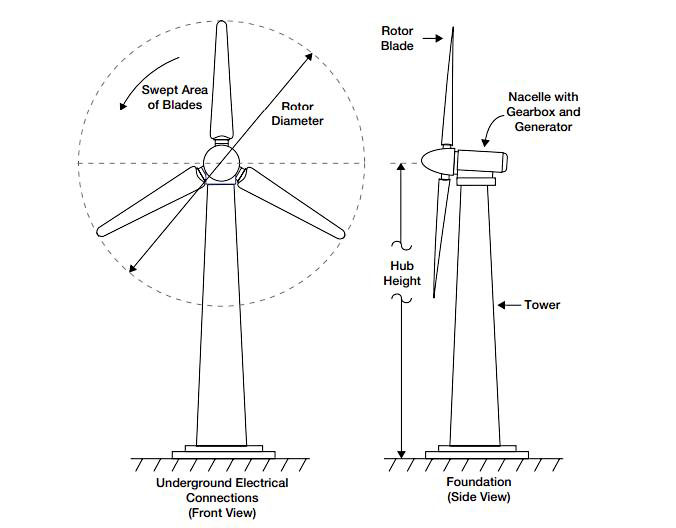

The horizontal axis, or propeller-type, approach currently dominates wind turbine applications. A horizontal axis wind turbine consists of a tower and a nacelle that is mounted on the top of the tower. The nacelle contains the generator, gearbox and the rotor. Different mechanisms exist to point the nacelle towards the wind direction or to move the nacelle out of the wind in the case of high wind speeds. On small turbines, the rotor and the nacelle are oriented into the wind with a tail vane. On large turbines, the nacelle with the rotor is electrically yawed into or out of the wind, in response to a signal from a wind vane.

Horizontal axis wind turbines typically use a different number of blades, depending on the purpose of the wind turbine. Two-bladed or three-bladed turbines are usually used for electricity power generation. Turbines with 20 or more blades are used for mechanical water pumping. The number of rotor blades is indirectly linked to the tip speed ratio, λ, which is the ratio of the blade tip speed and the wind speed:

Wind turbines with a high number of blades have a low tip speed ratio but a high starting torque. Wind turbines with only two or three blades have a high tip speed ratio but only a low starting torque. These turbines might need to be started if the wind speed reaches the operation range. A high tip speed ratio, however, allows the use of a smaller and therefore lighter gearbox to achieve the required high speed at the driving shaft of the power generator.

Currently, three-bladed wind turbines dominate the market for grid-connected, horizontal axis wind turbines. Three-bladed wind turbines have the advantage that the rotor moment of inertia is easier to understand and therefore often better to handle than the rotor moment of inertia of a two-bladed turbine. Furthermore, three-bladed wind turbines are often attributed better visual aesthetics and a lower noise level than two-bladed wind turbines. Both aspects are important considerations for wind turbine applications in highly populated areas.

Two-bladed wind turbines have the advantage that the tower top weight is lighter and therefore the whole supporting structure can be built lighter, and the related costs are very likely to be lower. As visual aesthetics and noise levels are less important offshore, the lower costs might be attractive and lead to the development of two-bladed turbines for the offshore market.

Wind turbines using aerodynamic lift can be further divided according to the orientation of the spin axis into horizontal axis and vertical axis turbines. Vertical axis turbines, also known as Darrieus turbines after the French engineer who invented them in the 1920s, use vertical, often slightly curved, symmetrical airfoils. Darrieus turbines have the advantage that they operate independently of the wind direction and that the gearbox and generating machinery can be placed at ground level. High torque fluctuations with each revolution, no self-starting capability as well as limited options for speed regulation in high winds are, however, major disadvantages. Vertical axis turbines were developed and commercially produced in the 1970s until the end of the 1980s. The largest vertical axis wind turbine was installed in Canada, the Ecole C with 4200 kW. Since the end of the 1980s, however, the research and development of vertical axis wind turbines has almost stopped worldwide.

The horizontal axis, or propeller-type, approach currently dominates wind turbine applications. A horizontal axis wind turbine consists of a tower and a nacelle that is mounted on the top of the tower. The nacelle contains the generator, gearbox and the rotor. Different mechanisms exist to point the nacelle towards the wind direction or to move the nacelle out of the wind in the case of high wind speeds. On small turbines, the rotor and the nacelle are oriented into the wind with a tail vane. On large turbines, the nacelle with the rotor is electrically yawed into or out of the wind, in response to a signal from a wind vane.

Horizontal axis wind turbines typically use a different number of blades, depending on the purpose of the wind turbine. Two-bladed or three-bladed turbines are usually used for electricity power generation. Turbines with 20 or more blades are used for mechanical water pumping. The number of rotor blades is indirectly linked to the tip speed ratio, λ, which is the ratio of the blade tip speed and the wind speed:

λ=ωR/V

where ω is the frequency of rotation, R is the radius of the aerodynamic rotor and V is the wind speed.Wind turbines with a high number of blades have a low tip speed ratio but a high starting torque. Wind turbines with only two or three blades have a high tip speed ratio but only a low starting torque. These turbines might need to be started if the wind speed reaches the operation range. A high tip speed ratio, however, allows the use of a smaller and therefore lighter gearbox to achieve the required high speed at the driving shaft of the power generator.

Currently, three-bladed wind turbines dominate the market for grid-connected, horizontal axis wind turbines. Three-bladed wind turbines have the advantage that the rotor moment of inertia is easier to understand and therefore often better to handle than the rotor moment of inertia of a two-bladed turbine. Furthermore, three-bladed wind turbines are often attributed better visual aesthetics and a lower noise level than two-bladed wind turbines. Both aspects are important considerations for wind turbine applications in highly populated areas.

Two-bladed wind turbines have the advantage that the tower top weight is lighter and therefore the whole supporting structure can be built lighter, and the related costs are very likely to be lower. As visual aesthetics and noise levels are less important offshore, the lower costs might be attractive and lead to the development of two-bladed turbines for the offshore market.

Post a Comment:

You may also like:

Featured Articles

Horizontal Axis vs. Vertical Axis

Wind turbines are machines that generate electricity from the kinetic energy of the wind. In history, they were more ...

Wind turbines are machines that generate electricity from the kinetic energy of the wind. In history, they were more ...

Wind turbines are machines that generate electricity from the kinetic energy of the wind. In history, they were more ...

Wind turbines are machines that generate electricity from the kinetic energy of the wind. In history, they were more ...Wind Turbine Glossary

Wind energy is the kinetic energy that is present in moving air. The amount of potential energy depends mainly on wind speed, but ...

Wind energy is the kinetic energy that is present in moving air. The amount of potential energy depends mainly on wind speed, but ...

Wind energy is the kinetic energy that is present in moving air. The amount of potential energy depends mainly on wind speed, but ...

Wind energy is the kinetic energy that is present in moving air. The amount of potential energy depends mainly on wind speed, but ...Household Wind Energy System Components

Basic parts of home wind energy systems generally comprise a rotor, a generator or alternator mounted on a frame, a tail ...

Basic parts of home wind energy systems generally comprise a rotor, a generator or alternator mounted on a frame, a tail ...

Basic parts of home wind energy systems generally comprise a rotor, a generator or alternator mounted on a frame, a tail ...

Basic parts of home wind energy systems generally comprise a rotor, a generator or alternator mounted on a frame, a tail ...What is a Wind Turbine?

Wind turbines are devices that convert the kinetic energy from the wind into mechanical power, which can then be used to generate ...

Wind turbines are devices that convert the kinetic energy from the wind into mechanical power, which can then be used to generate ...

Wind turbines are devices that convert the kinetic energy from the wind into mechanical power, which can then be used to generate ...

Wind turbines are devices that convert the kinetic energy from the wind into mechanical power, which can then be used to generate ...Overvoltage Protection for Wind ...

Due to their principle of operation, wind turbines have to be set up outdoors and are used in a wide range of ...

Due to their principle of operation, wind turbines have to be set up outdoors and are used in a wide range of ...

Due to their principle of operation, wind turbines have to be set up outdoors and are used in a wide range of ...

Due to their principle of operation, wind turbines have to be set up outdoors and are used in a wide range of ...