Home » Application » Wind Turbine for Onshore Application

Wind Turbine for Onshore Application

Modern, commercial grid-connected wind turbines have evolved from small, simple machines to large, highly sophisticated devices. Scientific and engineering expertise and advances, as well as improved computational tools, design standards, manufacturing methods, and O&M procedures, have all supported these technology developments. Onshore wind energy technologies are already being manufactured and deployed on a commercial basis, and are expected to further reduce the cost of wind energy while enhancing system and component performance and reliability.

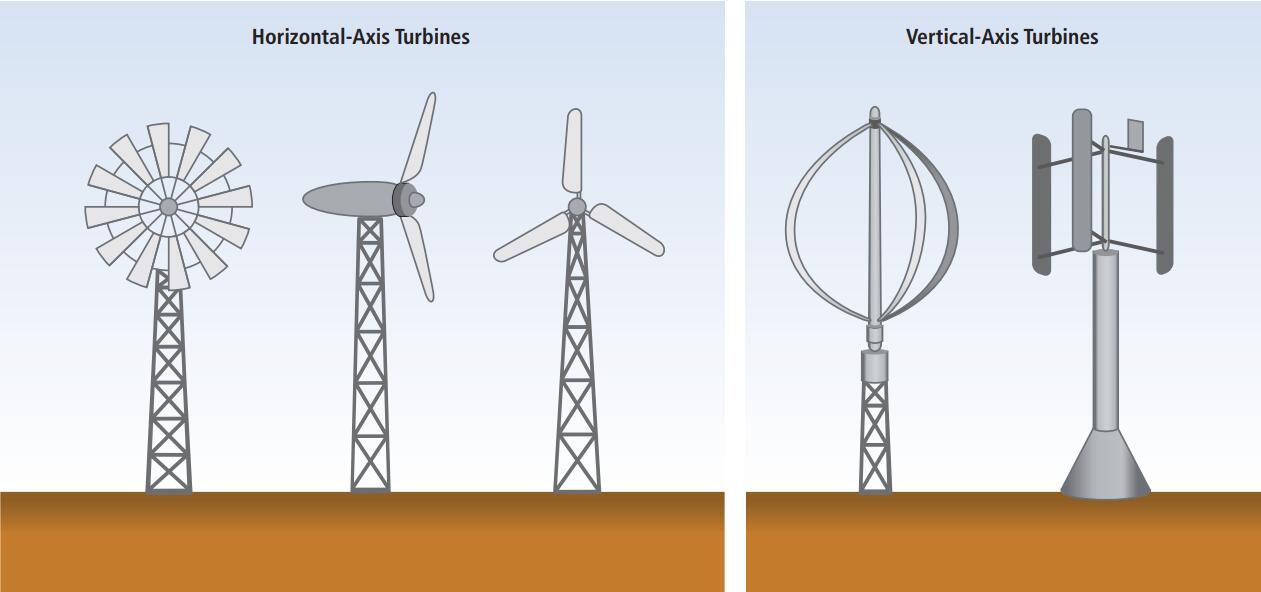

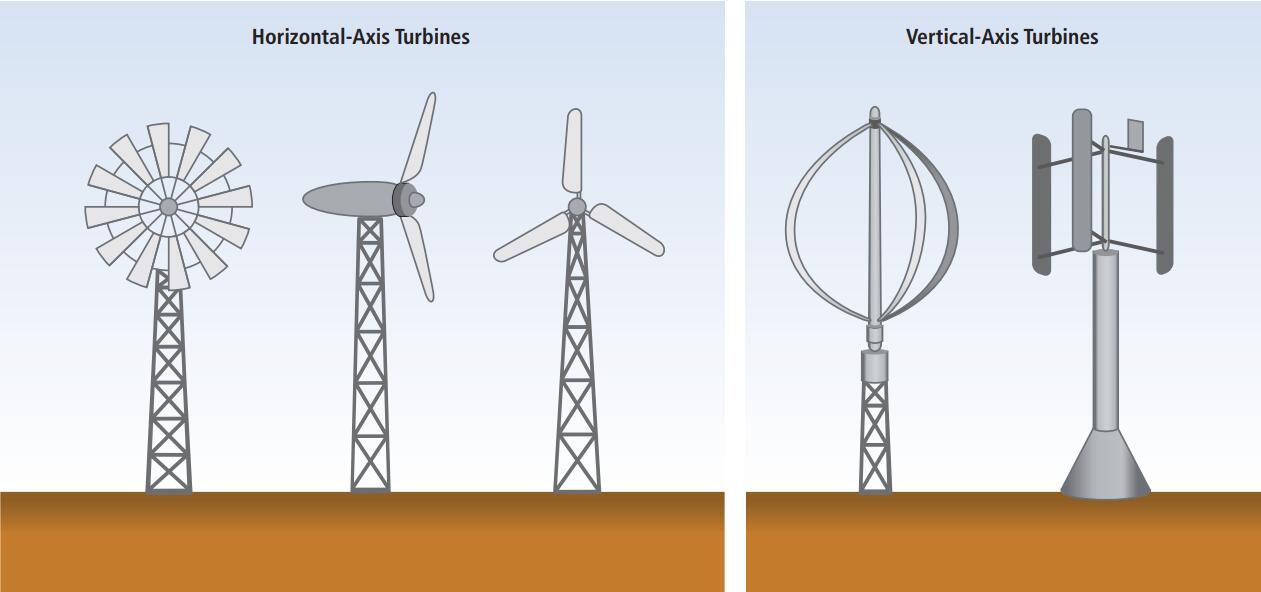

In the 1970s and 1980s, a variety of onshore wind turbine configurations were investigated, including both horizontal and vertical axis designs (Figure 1). Gradually, the horizontal axis design came to dominate, although configurations varied, in particular the number of blades and whether those blades were oriented upwind or downwind of the tower. Offshore wind energy technology is still developing, with greater opportunities for additional advancement.

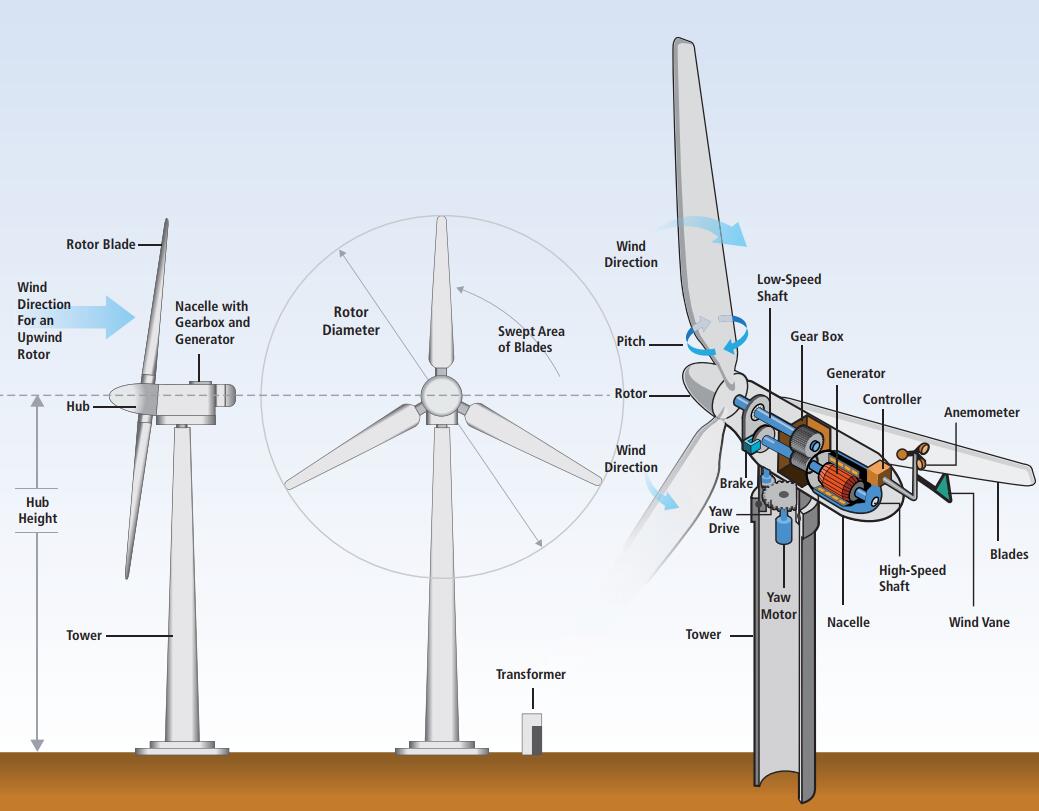

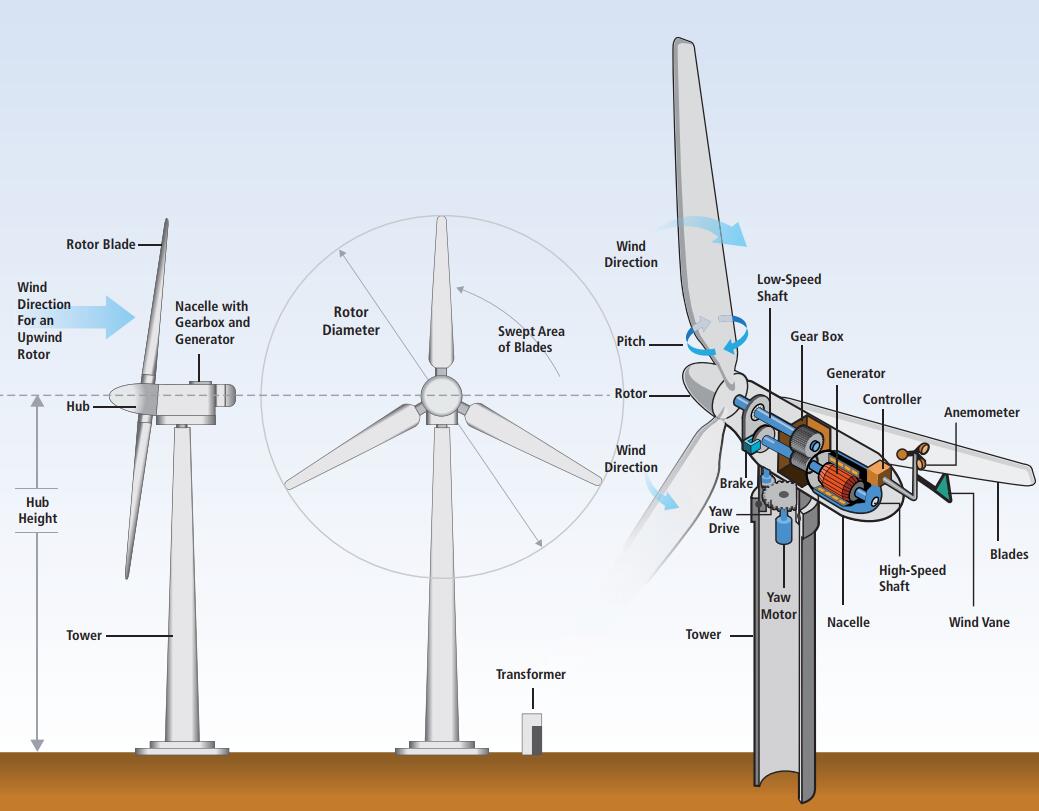

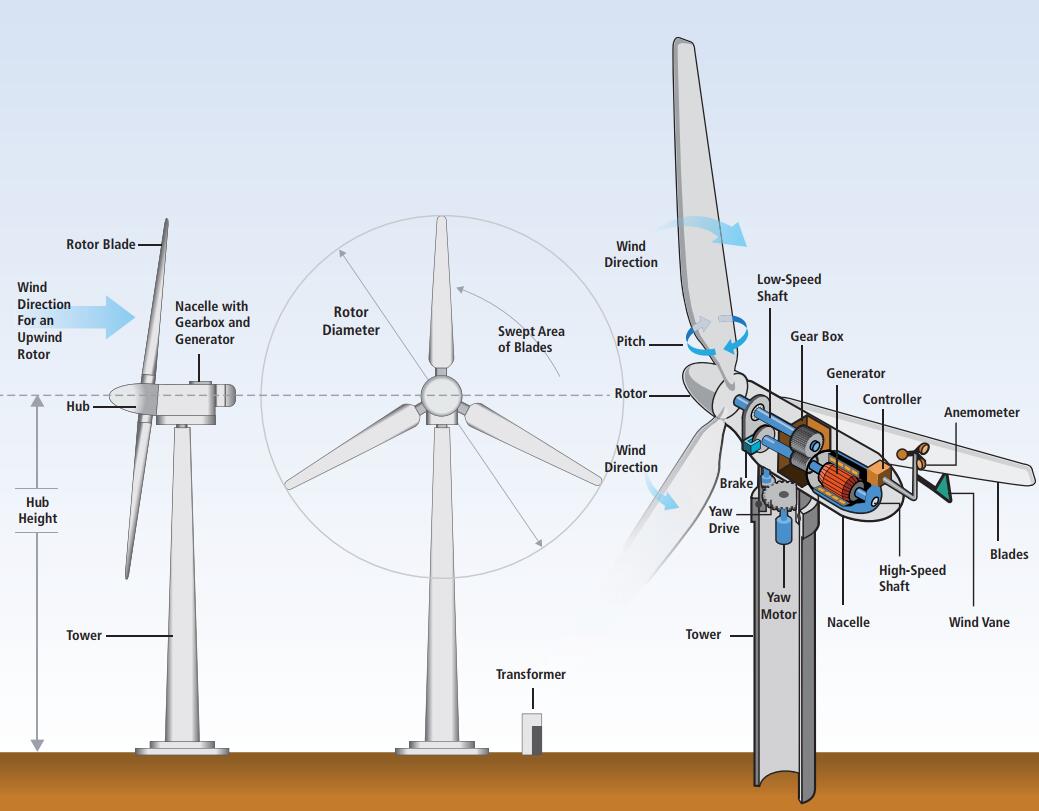

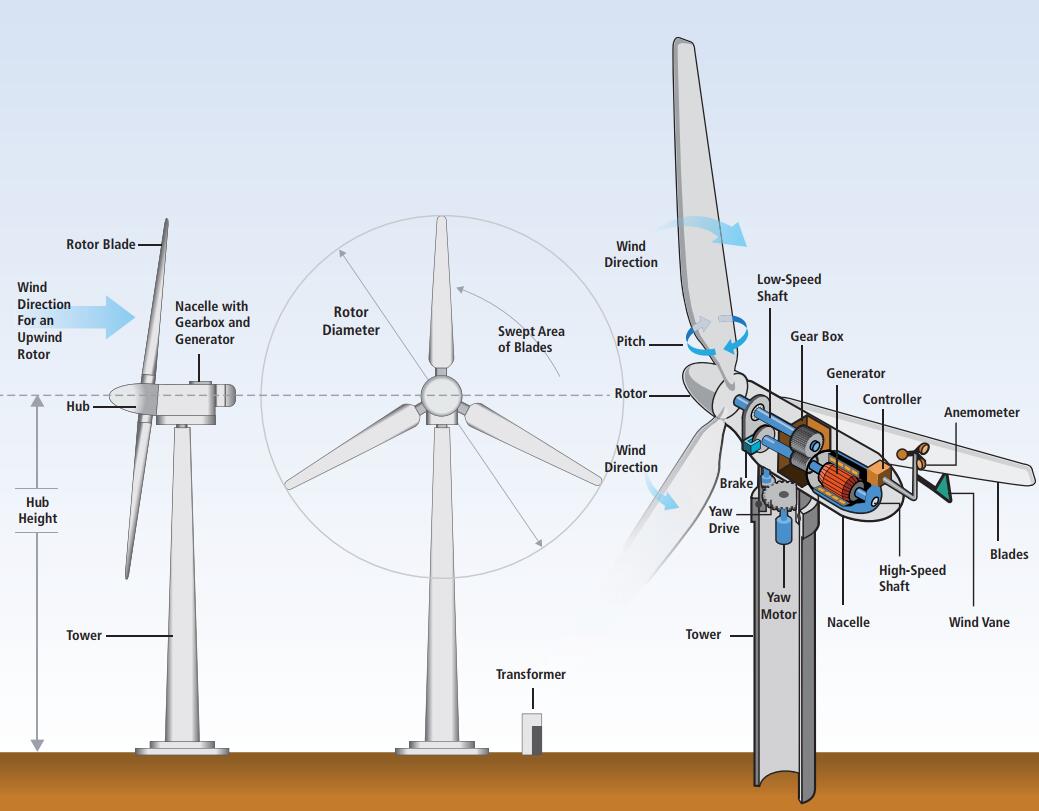

After a period of further consolidation, turbine designs largely centered (with some notable exceptions) around the three-blade, upwind rotor; locating the turbine blades upwind of the tower prevents the tower from blocking wind flow onto the blades and producing extra aerodynamic noise and loading, while three-bladed machines typically have lower noise emissions than two-bladed machines. The three blades are attached to a hub and main shaft, from which power is transferred (sometimes through a gearbox, depending on design) to a generator. The main shaft and main bearings, gearbox, generator and control system are contained within a housing called the nacelle. Figure 2 shows the components in a modern wind turbine with a gearbox; in wind turbines without a gearbox, the rotor is mounted directly on the generator shaft.

Figure 2

Figure 2

In the 1980s, larger machines were rated at around 100 kW and primarily relied on aerodynamic blade stall to control power production from the fixed blades. These turbines generally operated at one or two rotational speeds. As turbine size increased over time, development went from stall control to full-span pitch control in which turbine output is controlled by pitching (i.e., rotating) the blades along their long axis. In addition, a reduction in the cost of power electronics allowed variable speed wind turbine operation.

Initially, variable speeds were used to smooth out the torque fluctuations in the drive train caused by wind turbulence and to allow more efficient operation in variable and gusty winds. More recently, almost all electric system operators require the continued operation of large wind power plants during electrical faults, together with being able to provide reactive power: these requirements have accelerated the adoption of variable-speed operation with power electronic conversion. Modern wind turbines typically operate at variable speeds using full-span blade pitch control. Blades are commonly constructed with composite materials, and towers are usually tubular steel structures that taper from the base to the nacelle at the top.

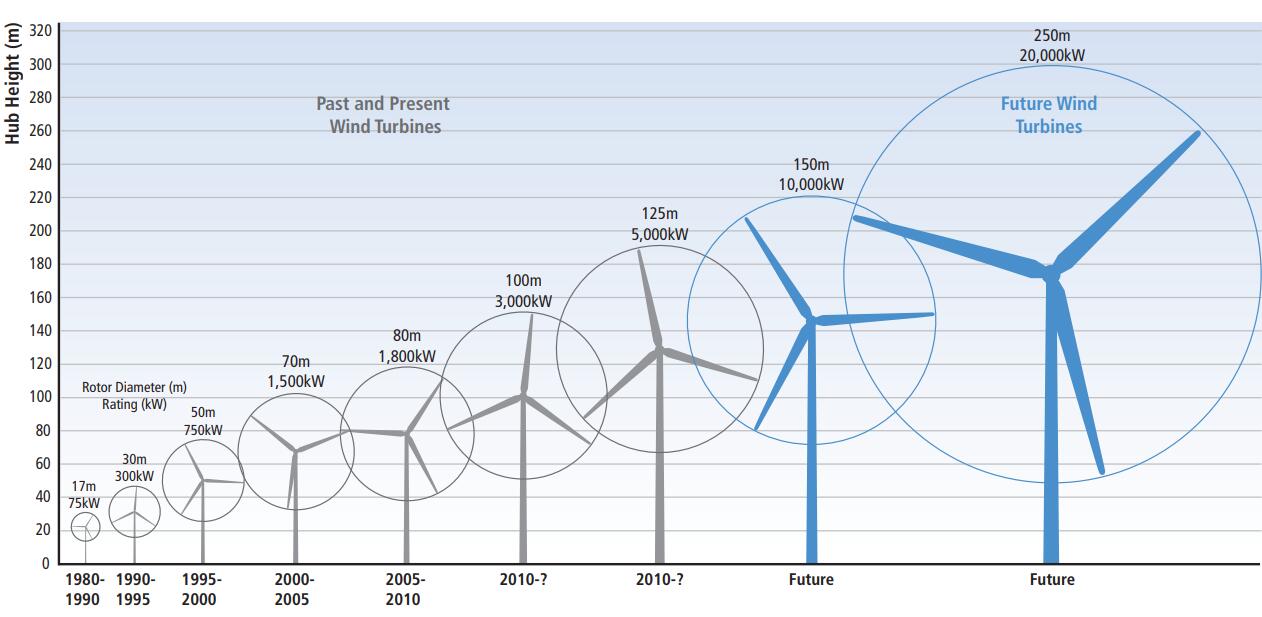

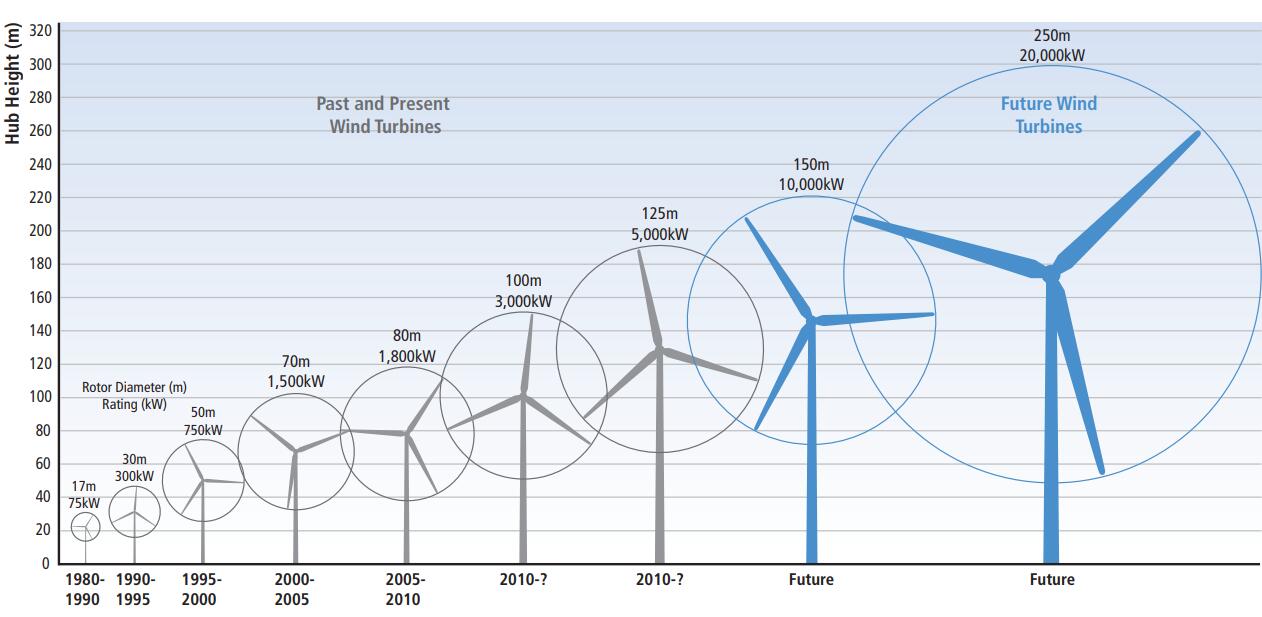

Over the past 30 years, average wind turbine size has grown significantly (Figure 3), with the largest fraction of onshore wind turbines installed globally in 2009 having a rated capacity of 1.5 to 2.5 MW; the average size of turbines installed in 2009 was 1.6 MW. As of 2010, wind turbines used onshore typically stand on 50- to 100-m towers, with rotors that are often 50 to 100 m in diameter; commercial machines with rotor diameters and tower heights in excess of 125 m are operating, and even larger machines are under development.

Modern turbines operate with rotational speeds ranging from 12 to 20 revolutions per minute (RPM), which compares to the faster and potentially more visually disruptive speeds exceeding 60 RPM common of the smaller turbines installed during the 1980s.13 Onshore wind turbines are typically grouped together into wind power plants, sometimes also called wind projects or wind farms. These wind power plants are often 5 to 300 MW in size, though smaller and larger plants do exist.

The main reason for the continual increase in turbine size to this point has been to minimize the levelized generation cost of wind energy by:

As a result of these and other developments, onshore wind energy technology is already being commercially manufactured and deployed on a large scale. Moreover, modern wind turbines have nearly reached the theoretical maximum of aerodynamic efficiency, with the coefficient of performance rising from 0.44 in the 1980s to about 0.50 by the mid-2000s.14 The value of 0.50 is near the practical limit dictated by the drag of aerofoils and compares with the Lanchester-Betz theoretical limit of 0.593.

The design requirement for wind turbines is normally 20 years with 4,000 to 7,000 hours of operation (at and below rated power) each year depending on the characteristics of the local wind resource. Given the challenges of reliably meeting this design requirement, O&M teams work to maintain high plant availability despite component failure rates that have, in some instances, been higher than expected. Though wind turbines are reportedly under-performing in some contexts, data collected through 2008 show that modern onshore wind turbines in mature markets can achieve an availability of 97% or more.

These results demonstrate that the technology has reached sufficient commercial maturity to allow large-scale manufacturing and deployment. Nonetheless, additional advances to improve reliability, increase electricity production and reduce costs are anticipated. Additionally, most of the historical technology advances have occurred in developed countries. Increasingly, however, developing countries are investigating the use of wind energy, and opportunities for technology transfer in wind turbine design, component manufacturing and wind power plant siting exist. Extreme environmental conditions, such as icing or typhoons, may be more prominent in some of these markets, providing impetus for continuing research. Other aspects unique to less-developed countries, such as minimal transportation infrastructure, could also influence wind turbine designs if and as these markets grow.

Moreover, optimizing turbine and power plant design for specific site conditions has become common as wind turbines, wind power plants and the wind energy market have all increased in size; site-specific conditions that can impact turbine and plant design include geographic and temporal variations in wind speed, site topography and access, interactions among individual wind turbines due to wake effects, and integration into the larger electricity system. Wind turbine and power plant design also impacts and is impacted by noise, visual, environmental and public acceptance issues.

In the 1970s and 1980s, a variety of onshore wind turbine configurations were investigated, including both horizontal and vertical axis designs (Figure 1). Gradually, the horizontal axis design came to dominate, although configurations varied, in particular the number of blades and whether those blades were oriented upwind or downwind of the tower. Offshore wind energy technology is still developing, with greater opportunities for additional advancement.

Figure 1

Figure 2

Figure 2

In the 1980s, larger machines were rated at around 100 kW and primarily relied on aerodynamic blade stall to control power production from the fixed blades. These turbines generally operated at one or two rotational speeds. As turbine size increased over time, development went from stall control to full-span pitch control in which turbine output is controlled by pitching (i.e., rotating) the blades along their long axis. In addition, a reduction in the cost of power electronics allowed variable speed wind turbine operation.

Initially, variable speeds were used to smooth out the torque fluctuations in the drive train caused by wind turbulence and to allow more efficient operation in variable and gusty winds. More recently, almost all electric system operators require the continued operation of large wind power plants during electrical faults, together with being able to provide reactive power: these requirements have accelerated the adoption of variable-speed operation with power electronic conversion. Modern wind turbines typically operate at variable speeds using full-span blade pitch control. Blades are commonly constructed with composite materials, and towers are usually tubular steel structures that taper from the base to the nacelle at the top.

Over the past 30 years, average wind turbine size has grown significantly (Figure 3), with the largest fraction of onshore wind turbines installed globally in 2009 having a rated capacity of 1.5 to 2.5 MW; the average size of turbines installed in 2009 was 1.6 MW. As of 2010, wind turbines used onshore typically stand on 50- to 100-m towers, with rotors that are often 50 to 100 m in diameter; commercial machines with rotor diameters and tower heights in excess of 125 m are operating, and even larger machines are under development.

Modern turbines operate with rotational speeds ranging from 12 to 20 revolutions per minute (RPM), which compares to the faster and potentially more visually disruptive speeds exceeding 60 RPM common of the smaller turbines installed during the 1980s.13 Onshore wind turbines are typically grouped together into wind power plants, sometimes also called wind projects or wind farms. These wind power plants are often 5 to 300 MW in size, though smaller and larger plants do exist.

Figure 3

The main reason for the continual increase in turbine size to this point has been to minimize the levelized generation cost of wind energy by:

- Increasing electricity production (taller towers provide access to a higher-quality wind resource, and larger rotors allow a greater exploitation of those winds as well as more cost-effective exploitation of lower-quality wind resource sites).

- Reducing investment costs per unit of capacity (installation of a fewer number of larger turbines can, to a point, reduce overall investment costs).

- Reducing O&M costs (larger turbines can reduce maintenance costs per unit of capacity).

As a result of these and other developments, onshore wind energy technology is already being commercially manufactured and deployed on a large scale. Moreover, modern wind turbines have nearly reached the theoretical maximum of aerodynamic efficiency, with the coefficient of performance rising from 0.44 in the 1980s to about 0.50 by the mid-2000s.14 The value of 0.50 is near the practical limit dictated by the drag of aerofoils and compares with the Lanchester-Betz theoretical limit of 0.593.

The design requirement for wind turbines is normally 20 years with 4,000 to 7,000 hours of operation (at and below rated power) each year depending on the characteristics of the local wind resource. Given the challenges of reliably meeting this design requirement, O&M teams work to maintain high plant availability despite component failure rates that have, in some instances, been higher than expected. Though wind turbines are reportedly under-performing in some contexts, data collected through 2008 show that modern onshore wind turbines in mature markets can achieve an availability of 97% or more.

These results demonstrate that the technology has reached sufficient commercial maturity to allow large-scale manufacturing and deployment. Nonetheless, additional advances to improve reliability, increase electricity production and reduce costs are anticipated. Additionally, most of the historical technology advances have occurred in developed countries. Increasingly, however, developing countries are investigating the use of wind energy, and opportunities for technology transfer in wind turbine design, component manufacturing and wind power plant siting exist. Extreme environmental conditions, such as icing or typhoons, may be more prominent in some of these markets, providing impetus for continuing research. Other aspects unique to less-developed countries, such as minimal transportation infrastructure, could also influence wind turbine designs if and as these markets grow.

Moreover, optimizing turbine and power plant design for specific site conditions has become common as wind turbines, wind power plants and the wind energy market have all increased in size; site-specific conditions that can impact turbine and plant design include geographic and temporal variations in wind speed, site topography and access, interactions among individual wind turbines due to wake effects, and integration into the larger electricity system. Wind turbine and power plant design also impacts and is impacted by noise, visual, environmental and public acceptance issues.

Post a Comment:

You may also like:

Featured Articles

History of Wind Energy Applications

Wind is used to produce electricity by converting the kinetic energy of air in motion into electricity. In modern wind ...

Wind is used to produce electricity by converting the kinetic energy of air in motion into electricity. In modern wind ...

Wind is used to produce electricity by converting the kinetic energy of air in motion into electricity. In modern wind ...

Wind is used to produce electricity by converting the kinetic energy of air in motion into electricity. In modern wind ...Application in Energy Storage

With the development of science and technology, energy storage is one of the most effective ways to solve the problem of ...

With the development of science and technology, energy storage is one of the most effective ways to solve the problem of ...

With the development of science and technology, energy storage is one of the most effective ways to solve the problem of ...

With the development of science and technology, energy storage is one of the most effective ways to solve the problem of ...Application in Severe Climates

Operation in severe climates imposes special design considerations on wind turbines. Severe climates may include those with ...

Operation in severe climates imposes special design considerations on wind turbines. Severe climates may include those with ...

Operation in severe climates imposes special design considerations on wind turbines. Severe climates may include those with ...

Operation in severe climates imposes special design considerations on wind turbines. Severe climates may include those with ...Applications for Small Wind Turbines

Small-scale wind energy is a small but rapidly growing segment of the RE industry in the US. Like other renewable sources, in its ...

Small-scale wind energy is a small but rapidly growing segment of the RE industry in the US. Like other renewable sources, in its ...

Small-scale wind energy is a small but rapidly growing segment of the RE industry in the US. Like other renewable sources, in its ...

Small-scale wind energy is a small but rapidly growing segment of the RE industry in the US. Like other renewable sources, in its ...Wind Turbine for Onshore Application

Modern, commercial grid-connected wind turbines have evolved from small, simple machines to large,highly ...

Modern, commercial grid-connected wind turbines have evolved from small, simple machines to large,highly ...

Modern, commercial grid-connected wind turbines have evolved from small, simple machines to large,highly ...

Modern, commercial grid-connected wind turbines have evolved from small, simple machines to large,highly ...